Troubleshooting Common Home Brewing Problems: Bottling Issues, Sticking Fermentations & More

Even experienced brewers encounter problems! Brewing isn’t always a smooth process, and setbacks happen. This article tackles common brewing challenges, from stuck fermentations and off-flavors to gushing bottles and hazy beer. We provide clear explanations of the causes and offer practical solutions to get your brews back on track. Whether you're just starting out or a seasoned pro, understanding these issues and how to resolve them is a key part of the brewing journey. Many new brewers find that getting the basics right is the biggest challenge, so check out our guide to choosing your first home brewing kit for a solid foundation!

Understanding the Basics of Troubleshooting

Before diving into specific problems, it's important to understand that brewing is a science (and a little bit of an art!). Tiny variations in temperature, ingredients, or sanitation can significantly impact the outcome. Precise record-keeping (a brewing log!) is invaluable for diagnosing issues. Note your process details: mash temps, fermentation temps, gravity readings, and any deviations from your recipe. A well-maintained log can often pinpoint the root cause of a problem, saving you time and frustration.

Common Brewing Problems and Solutions

Let's break down some frequent hurdles home brewers face:

1. Stuck Fermentation

The Problem: Your fermentation stops prematurely. Gravity readings remain unchanged, and your beer isn’t finishing. This can be incredibly frustrating, especially when you're eagerly awaiting that first taste!

Possible Causes:

>Temperature Shock: Rapid temperature fluctuations stress the yeast. This is especially true when using a temperature-sensitive yeast strain.

>Yeast Health: Old, under-pitched, or stressed yeast. The viability of your yeast is paramount for a healthy fermentation.

>Nutrient Deficiency: Yeast needs nutrients like nitrogen to thrive. A lack of these nutrients can significantly slow or halt fermentation.

>High Alcohol Tolerance: Very high gravity beers can be difficult for some yeast strains to complete. Choosing a yeast strain appropriate for the gravity is important.

Solutions:

>Warm Up: Gently raise the fermentation temperature. Small, incremental increases are best.

>Pitch More Yeast: A yeast starter is often necessary for high-gravity beers, ensuring a sufficient cell population.

>Add Yeast Nutrient: Add a yeast nutrient like Fermaid O or Go-Ferm. These nutrients provide the building blocks for yeast reproduction and activity.

>Repitch a Starter: If possible, take a small portion of the beer and repitch it with fresh yeast. This can often revive a stalled fermentation.

2. Off-Flavors (e.g., Diacetyl, Acetaldehyde)

The Problem: Your beer tastes "buttery" (diacetyl) or "green apple" like (acetaldehyde). These off-flavors can ruin an otherwise promising brew.

Possible Causes:

>Diacetyl: Yeast stress, insufficient wort aeration, warm fermentation. Diacetyl production is often a sign of yeast struggling to complete its work.

>Acetaldehyde: Young beer, incomplete fermentation, yeast stress. Acetaldehyde tends to dissipate over time, but can be unpleasant in the short term.

Solutions:

>Fermentation Temperature Control: Maintain the correct temperature range for your yeast. This is arguably the most crucial factor in avoiding off-flavors.

>Wort Aeration: Ensure your wort is well aerated before pitching yeast. Yeast needs oxygen to initially multiply and thrive.

>Time & Aging: Allow the beer to age longer; these flavors often dissipate. Patience is key in brewing.

3. Bottling Issues (Gushing, Sediment)

The Problem: Bottles erupt violently (gushing) or have excessive sediment. These issues can be messy and detract from the overall drinking experience.

Possible Causes:

>Gushing: Under-carbonation, residual sugars, wild yeast. This is a dramatic and potentially dangerous outcome.

>Sediment: Proteins, hop debris, yeast. While some sediment is normal, excessive amounts can indicate a problem.

Solutions:

>Carbonation: Ensure correct priming sugar amount for carbonation. Precise measurements are crucial for proper carbonation.

>Cold Crash: Cool the beer rapidly before bottling to help sediment settle. This clarifies the beer and reduces sediment.

>Finings: Use fining agents like Irish moss or gelatin to remove haze and sediment. These agents help bind and remove particles.

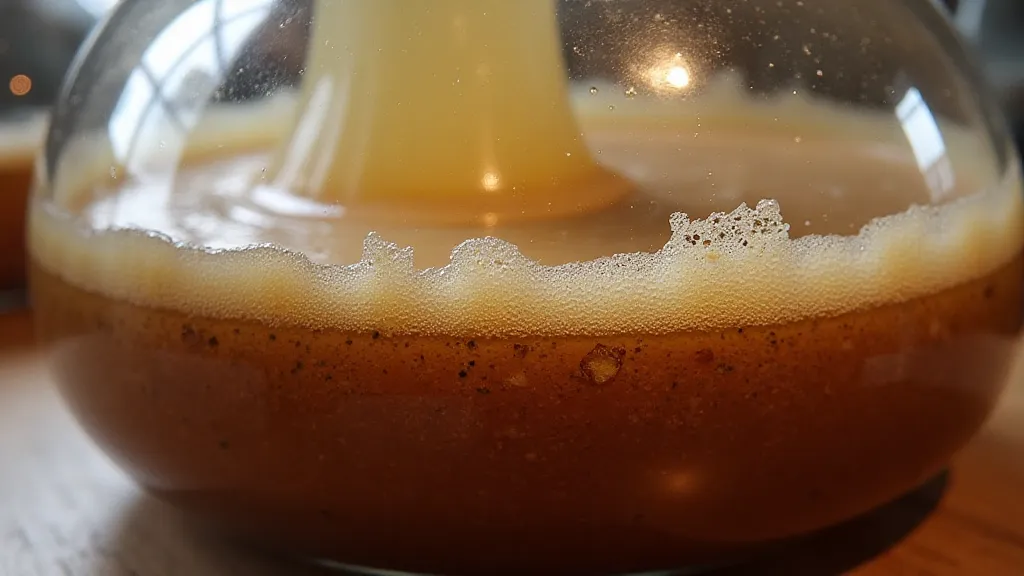

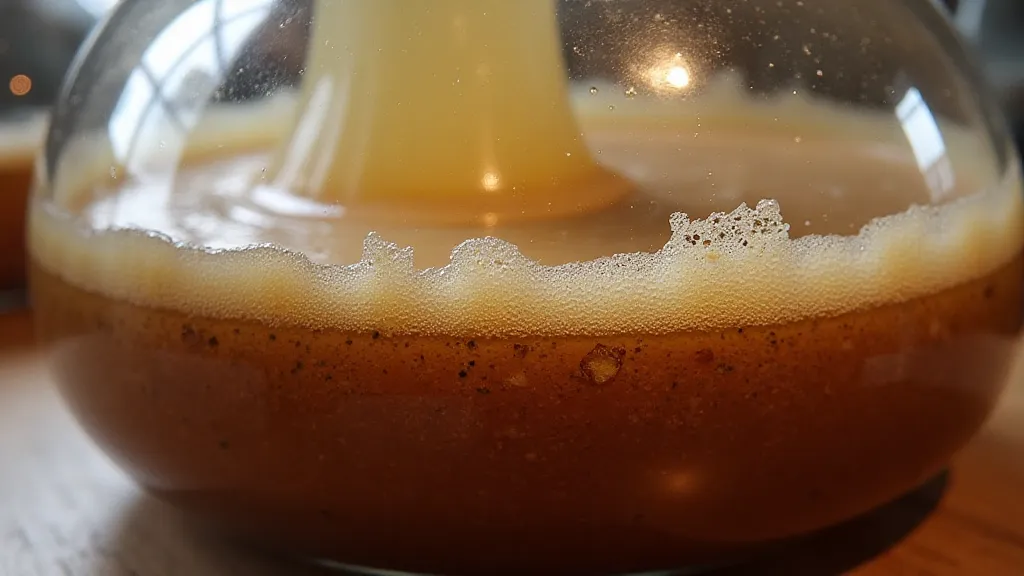

4. Haziness (Cloudy Beer)

The Problem: Your beer isn’t clear and appears cloudy. While a certain amount of haze can be acceptable in some styles, excessive cloudiness is often undesirable.

Possible Causes:

>Proteins: Breakdown of proteins during the mash. Protein haze is a common issue, especially in beers with a high malt content.

>Chill Haze: Complex carbohydrates that precipitate at cold temperatures. Chill haze is often harmless but can be aesthetically unappealing.

>Yeast: Residual yeast cells. While these cells are harmless, they contribute to haze.

Solutions:

>Mash pH: Adjust mash pH to optimize protein breakdown. Proper pH control is essential for efficient mash conversion.

>Irish Moss: Add Irish moss or other fining agents during the boil. These fining agents help remove haze-causing particles.

>Cold Crash: Chill the beer to near freezing to help haze drop out. This is a simple and effective way to clarify beer.

5. Sour or Off-Flavor Development

The Problem: Your beer has an undesirable sour or "barnyard" aroma and taste. These flavors are a clear indication of contamination.

Possible Causes:

>Wild Yeast/Bacteria: Contamination from unwanted microorganisms. Wild yeasts and bacteria can drastically alter the flavor profile of your beer.

>Lactobacillus: Produces lactic acid, causing sourness. Lactobacillus is a common culprit in sour beer contamination.

Solutions:

>Sanitation: Strict adherence to sanitation practices. Sanitation is the single most important aspect of brewing.

>Wort pH: Adjust wort pH to inhibit bacterial growth. Proper pH control can help prevent bacterial contamination.

Sometimes, you might want to intentionally ferment your beer with fruit to add unique flavor profiles. If you're looking to explore adding those extra layers of complexity, check out our guide to homebrewing with fruit.

Summary Table

| Problem |

Possible Cause(s) |

Solution(s) |

| Stuck Fermentation |

Temperature shock, yeast health, nutrient deficiency |

Warm up, pitch more yeast, add yeast nutrient |

| Off-Flavors (Diacetyl) |

Yeast stress, warm fermentation |

Temperature control, wort aeration |

| Gushing Bottles |

Under-carbonation, residual sugars, wild yeast |

Carbonation: Ensure correct priming sugar amount |

| Haziness |

Proteins, chill haze, yeast |

Adjust mash pH |

| Sour/Off Flavors |

Wild Yeast/Bacteria, Lactobacillus |

Sanitation |

Troubleshooting brewing issues can be a learning process. Remember to keep detailed notes, experiment with different techniques, and don't be afraid to try new things! And if you’re looking to expand your range of beer styles, exploring different fruits can be a great way to do so.